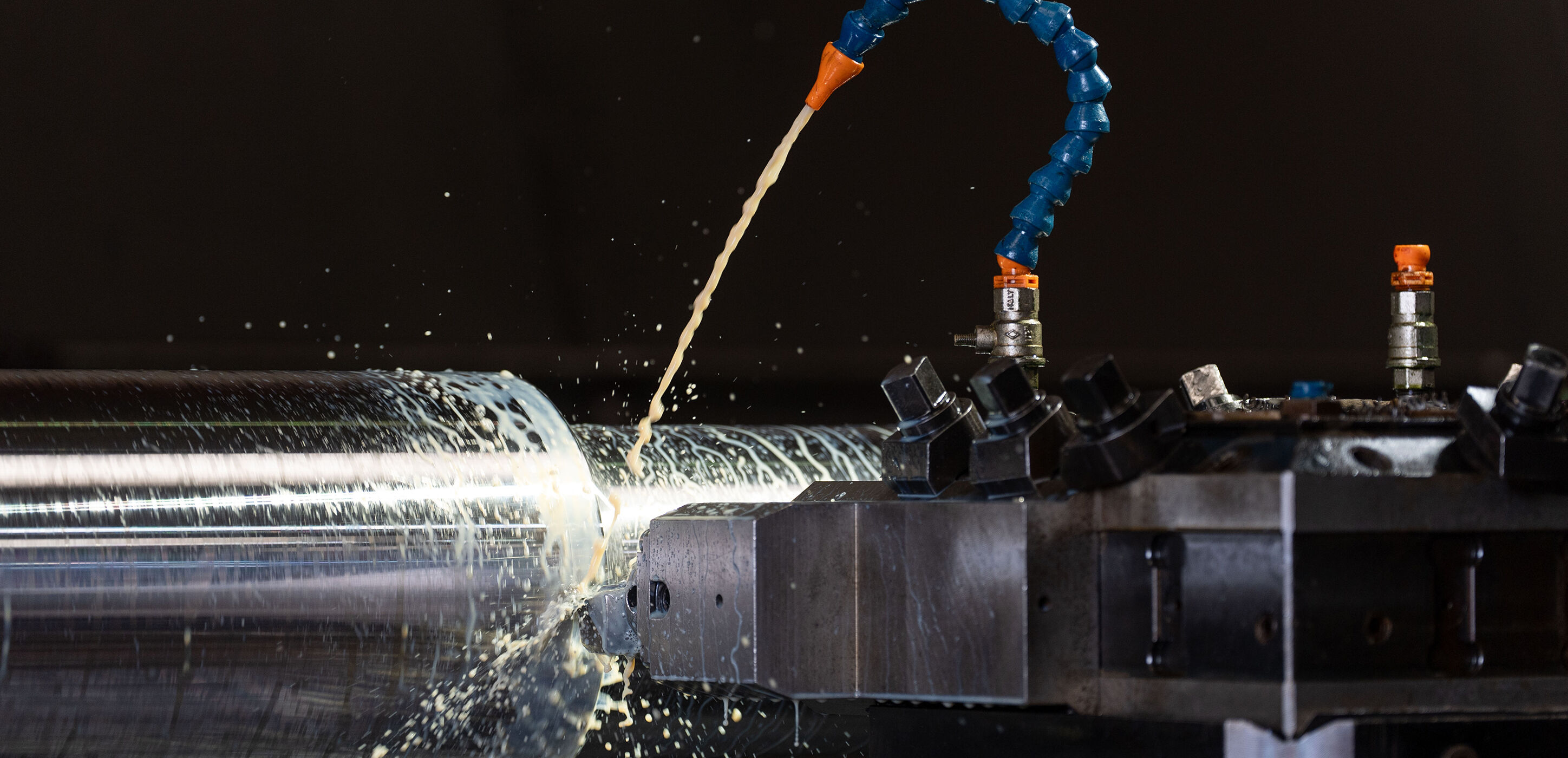

Belmar’s extensive Horizontal and Vertical Turning capacity across 7 CNC machines can manufacture up to Ø1,750 mm (Ø1,500 mm over slide on Horizontal Lathes) and up to 10,000mm in length (3,500 mm ID) and 8 tonne load weight (dependant on component type).

All Horizontal machines have roller steadies as standard which can handle up to Ø1,250 mm and impressive range of anti-vibration boring bars up to 1,500 mm long. All machines are supported with full (DNC linked) offline Programming Facilities using the Autodesk Fusion and Cimco software.

Our Turning Capability

Tacchi HD-1450

Hollow Spindle Lathe

Swing over bed

1450mm

Swing over saddle

1000mm

Between centres

4000mm

Bed length

4500mm

Chuck size

1000mm

Hollow spindle

500mm

Max weight

15000kg

CNC control Siemens

840D

Mori Seiki SL

CNC Horizontal Slant Bed Lathe

Swing over bed

1000mm

Swing over saddle

1000mm

Between centres

2000mm

Bed length

2500mm

Chuck size

630mm

CNC control Siemens

Fanuc

Additions

Hydraulic Steadies

Hydraulic Chuck

Powered Tailstock

Giddings & Lewis VTC-1600

CNC Vertical Lathe

Swing

2000mm

Height

2200mm

Chuck size

1700mm

Max weight

8000kg

CNC control Siemens

Fanuc

Our Products

From standard to high spec one off projects; from raw billet to finished product.

Belmar’s main products are components for subsea systems, including as standard Lubricator Valves, Accumulator Mandrels, Retainer Valves, Shear Subs, Subsea Test Trees, and THRT Adapters. We also produce components for Subsea Production Trees.