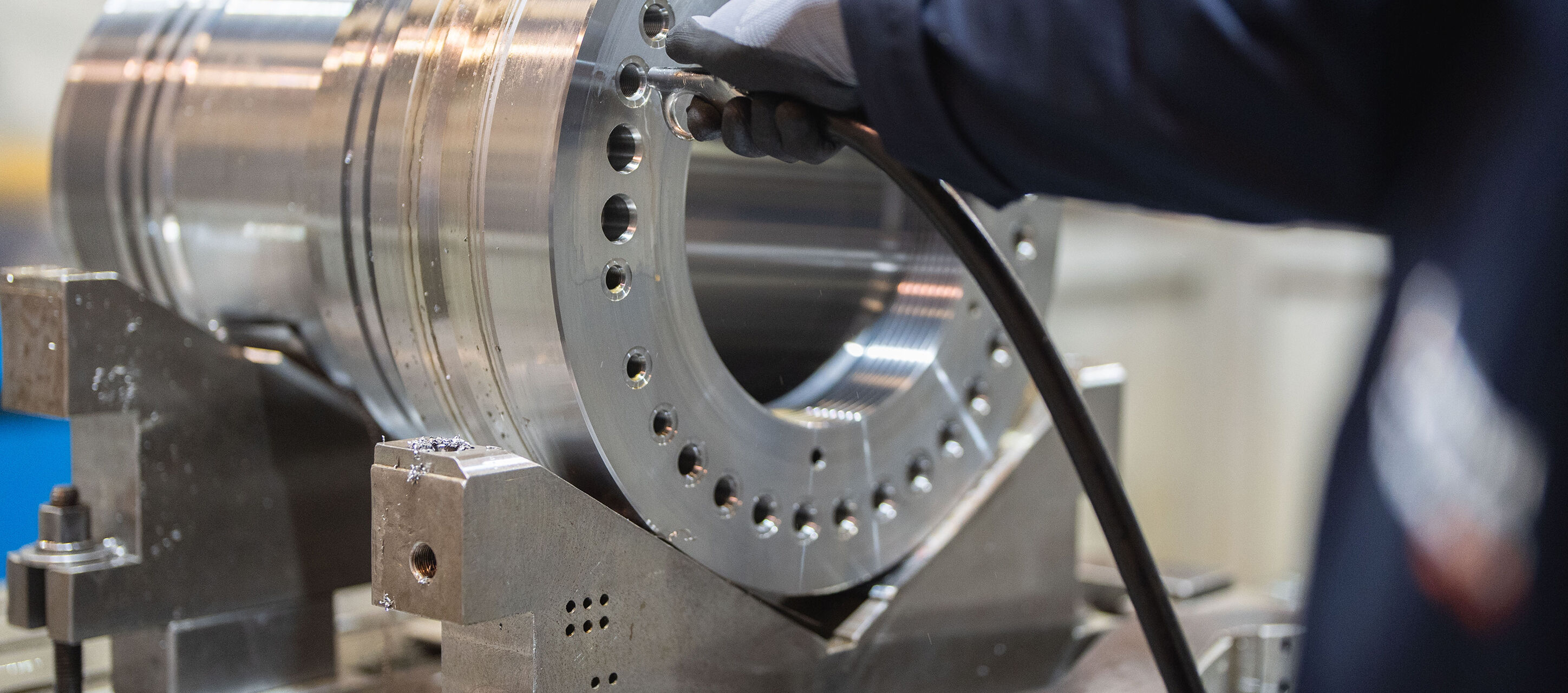

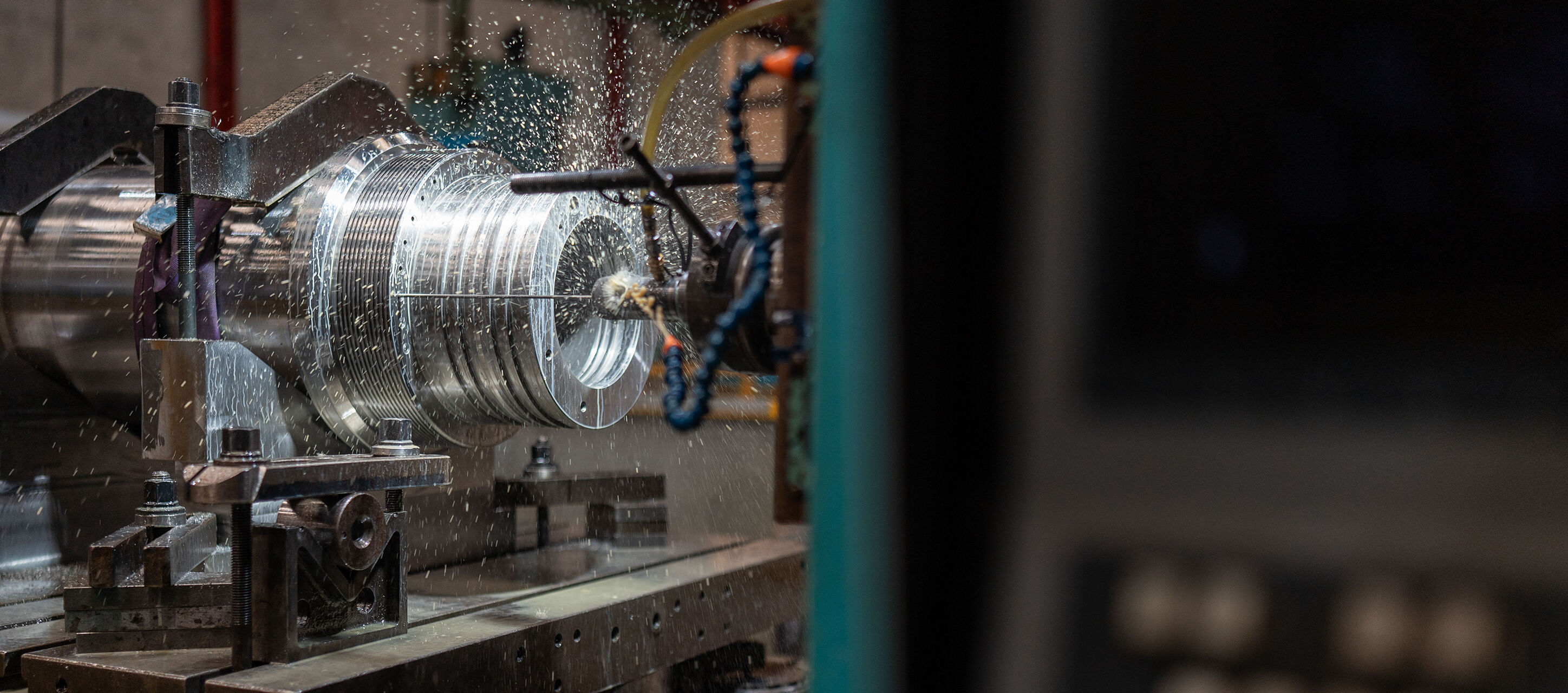

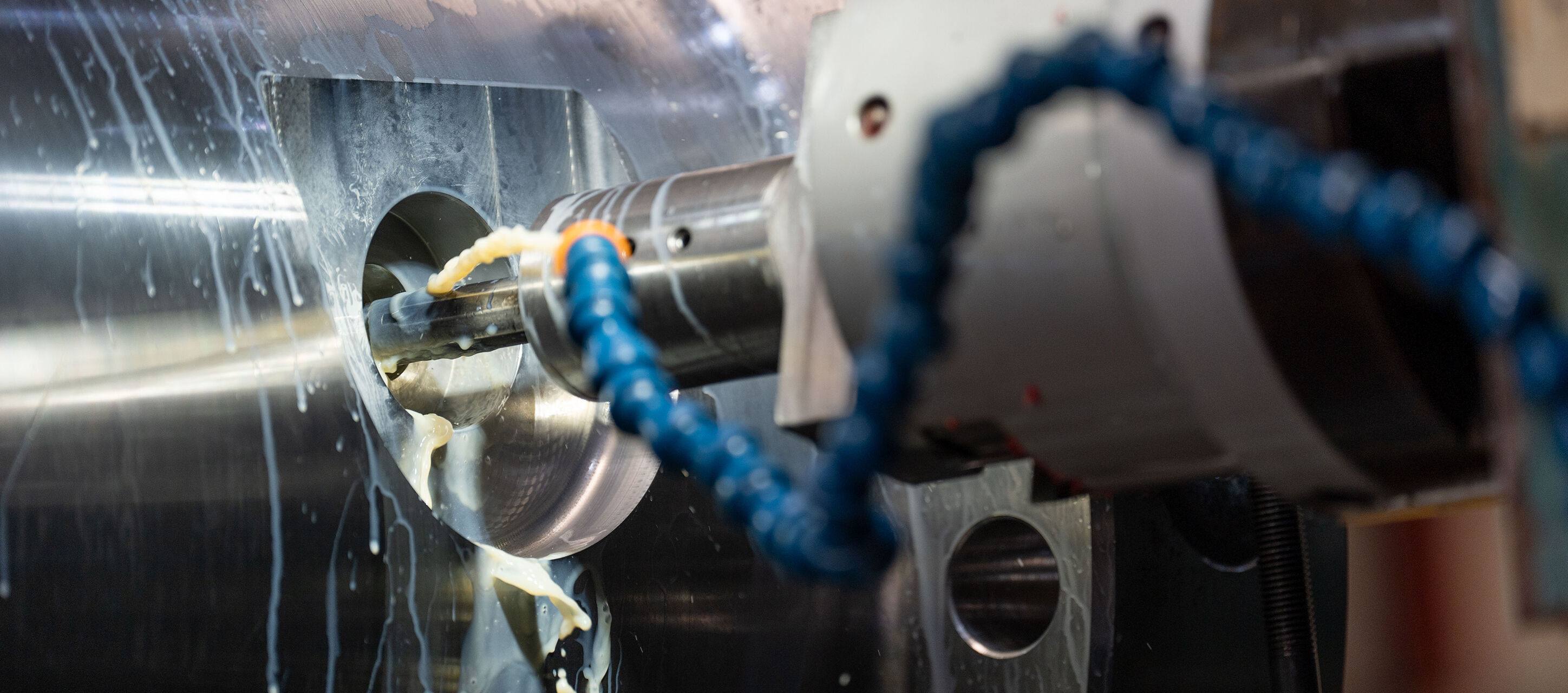

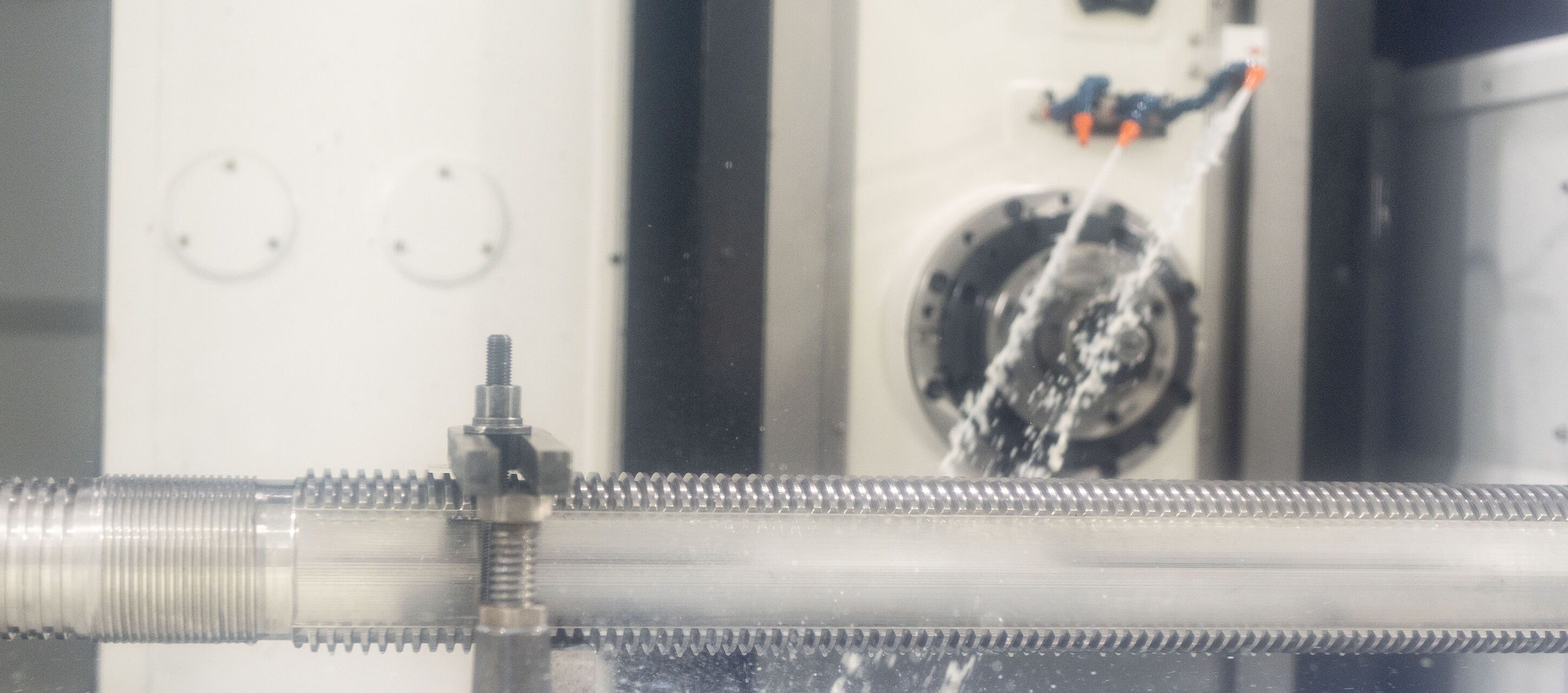

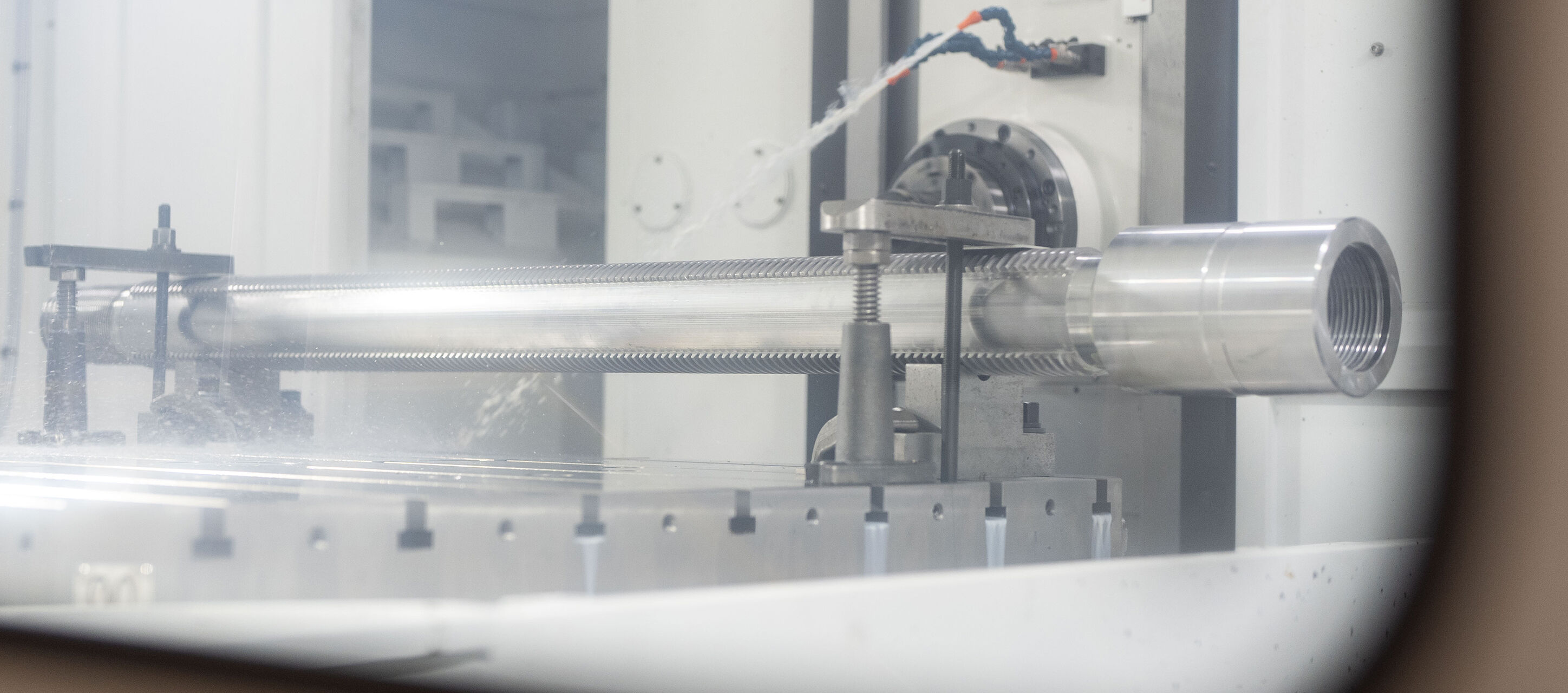

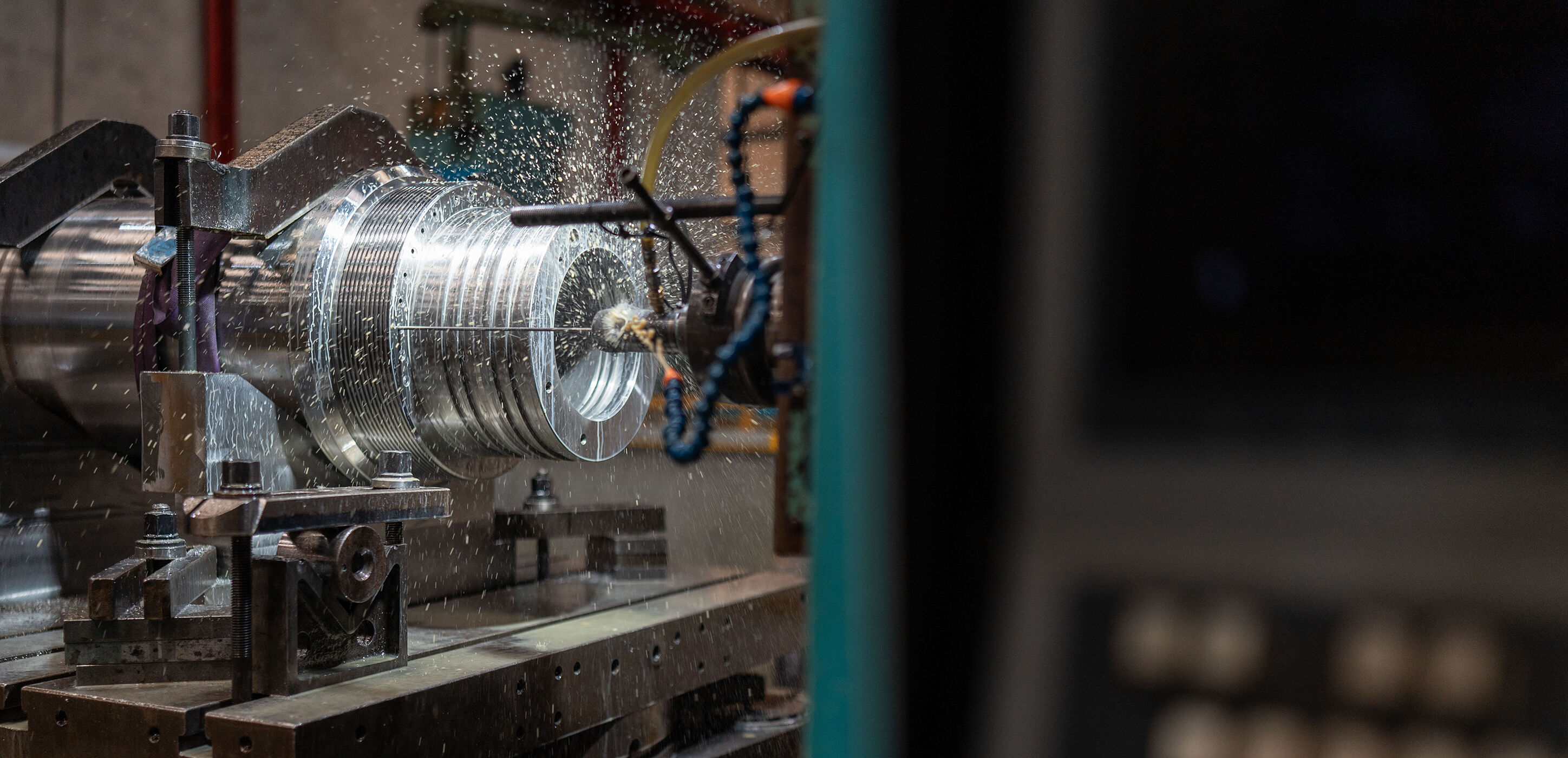

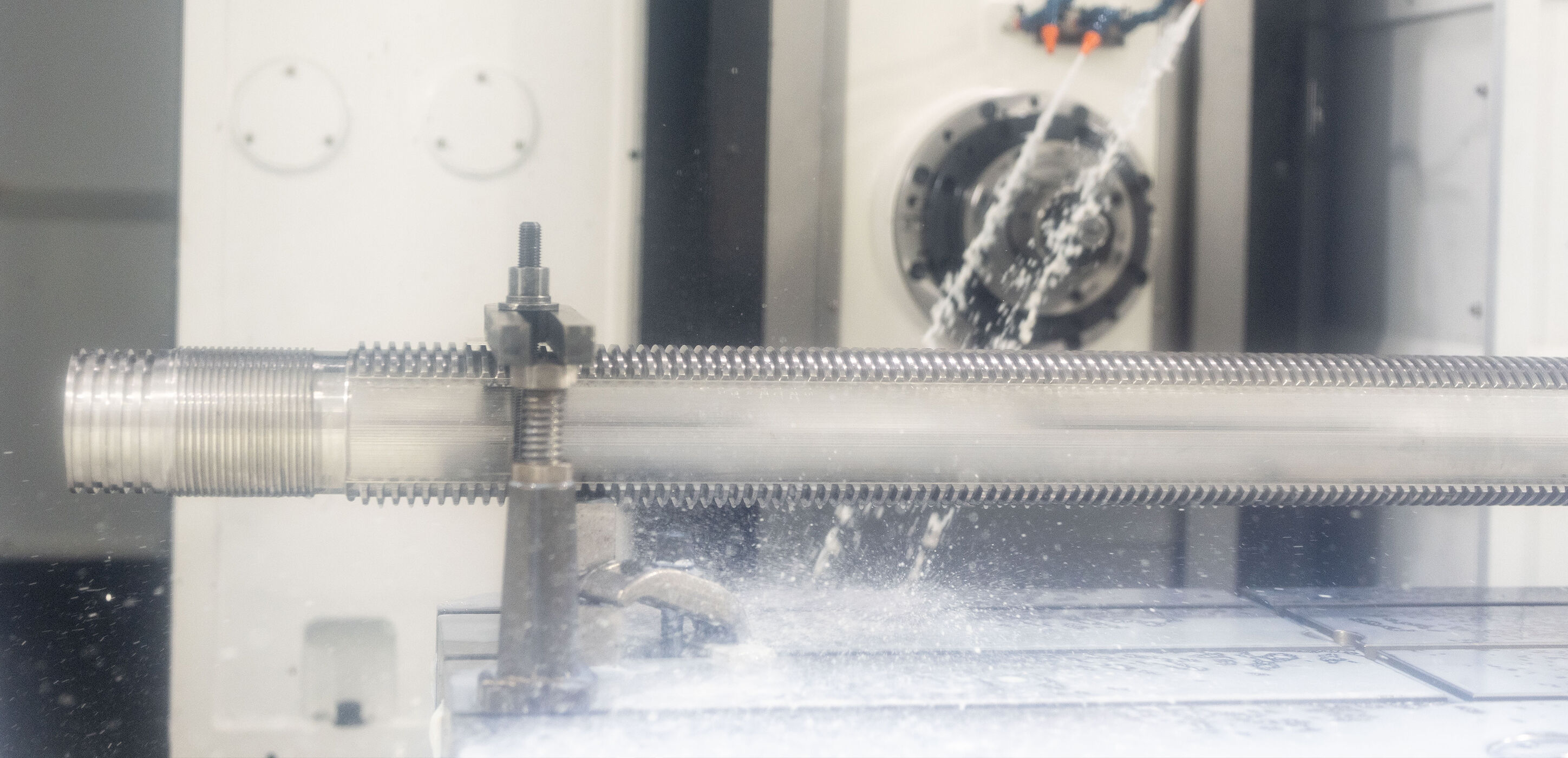

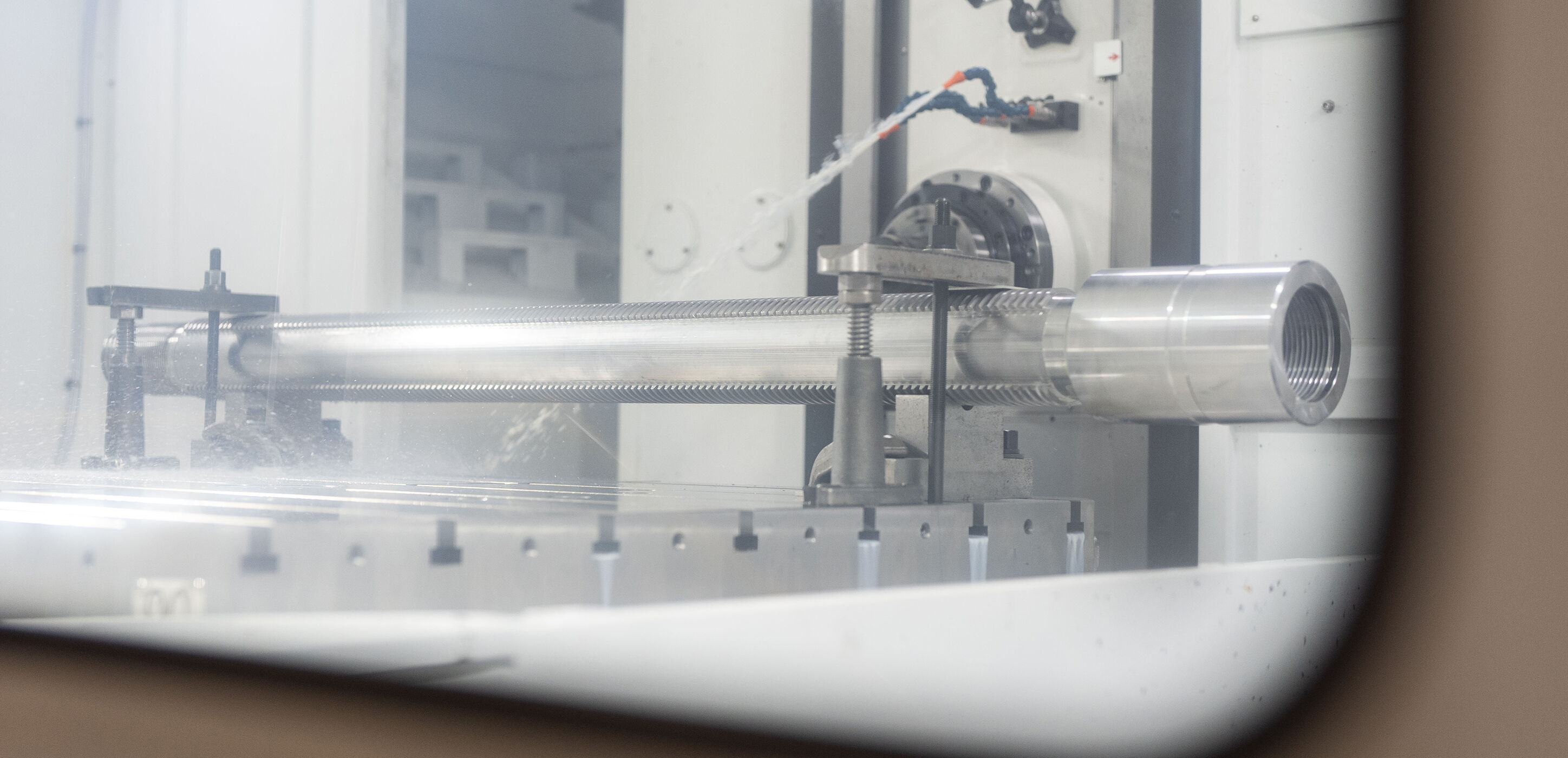

Belmar’s extensive Horizontal Boring and Milling capacity across 16 CNC machines can manufacture individual parts up to 12,000 KG’s in weight within a working envelope of 2,500 mm cube.

Standard component features commonly performed at Belmar are: Pressure Retaining Porting Configurations, Sealing Interface Profiles, Valve Seat Pockets, Internal Profiling, Bottle Boring, Gundrilling.

All Borers have their own contouring heads and can support a full range of outfacing bars available for deep bore internal profiling. All machines are supported with full (DNC linked) offline Programming Facilities using the Autodesk Fusion and Cimco software.

OUR Boring & Milling CAPABILITY

Hartford Borer Machining Centres

Hartford Borer

Table Size

1,400 x 1,600 mm

Max Load

8,000 KG

Axis Travel – X

2,000 mm

Axis Travel - Y

1,600 mm

Axis Travel - Z

1,500 mm

Axis Travel - W

500 mm

B (Rotary Table)

360°

Tool Management and Measurement

60 Tool Carousel, Renishaw Tool Setting and Spindle Probe

Our Products

From standard to high spec one off projects; from raw billet to finished product.

Belmar’s main products are components for subsea systems, including as standard Lubricator Valves, Accumulator Mandrels, Retainer Valves, Shear Subs, Subsea Test Trees, and THRT Adapters. We also produce components for Subsea Production Trees.